CIVS Graduate Research Assistant, Shiyu Wang, Successfully Defends Master’s Thesis

Congratulations to CIVS Graduate Research Assistant, Shiyu Wang, on successfully defending her Master’s Thesis “Numerical Simulation of AC/DC EAF Operations: Validation and Performance” on July 15.

Congratulations to CIVS Graduate Research Assistant, Shiyu Wang, on successfully defending her Master’s Thesis “Numerical Simulation of AC/DC EAF Operations: Validation and Performance” on July 15.

Shiyu will receive her MSME degree this summer. She started to conduct research at CIVS since her senior year and will continue to conduct her Ph.D. Thesis research at CIVS for her Ph.D. ME degree at Purdue University under supervision of CIVS Director Prof. Chenn Zhou, Professor by Courtesy at Purdue University’s School of Mechanical Engineering.

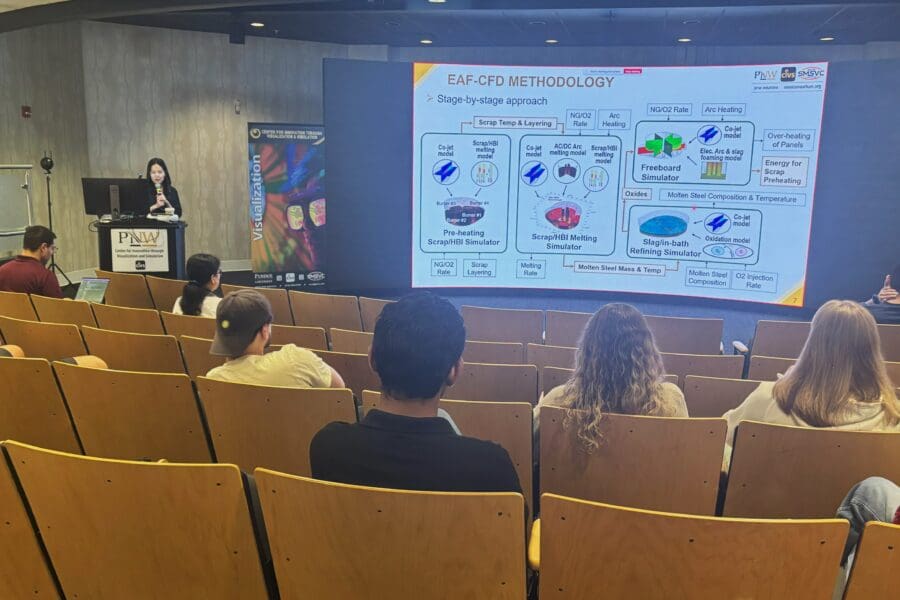

This study focuses on integrated computational fluid dynamic (CFD) modeling of electric arc furnaces (EAFs), with an emphasis on optimizing AC and DC EAF operations through realistic simulation of scrap melting processes. EAFs combine electrical and chemical energy to melt scrap steel, so improving energy efficiency and process control is critical for industrial-scale steelmaking. A comprehensive EAF CFD tool was developed and validated using data from real industrial furnaces. The models simulate coupled multiphysics phenomena including arc heating, coherent jet interaction, burner performance, scrap collapse, electrode motion, and heat transfer. The same modeling framework is applied to both AC and DC EAFs, with differences primarily in the electric arc representation. AC EAF tap-to-tap CFD simulation performed at NLMK demonstrated <5% deviation in electrode positioning and captured melting rate with high accuracy. Transient melting behaviors such as layering effects, re-solidification beneath electrodes, and bottom-up melting modes were also successfully reproduced. DC EAF simulations applied to actual SSAB furnace data validated key process variables: the predicted average melting rate differed from the measured value by approximately 13%, and during the main melting stage, the lowest electrode position showed less than 5% deviation from measurements. Following DC EAF model’s validation, parametric studies revealed that DC electrode arc power can impact melting time, with 10% to 20% arc power reduction extending melting by up to two minutes. Validated CFD models captured key process variables including melting rate and electrode behavior in both AC and DC EAF. The simulations quantify how arc power, burner use, and scrap layering conditions affect energy use and melt quality, offering practical guidance for optimizing industrial EAF operations.

At CIVS, I conducted on-site research at SMSVC steel plants, which helped me better understand the practical needs behind my project. The lab’s collaborative environment meant I received continuous support from both peers, mentors, and professors. These experiences directly improved my technical skills, communication abilities, and confidence in solving real engineering problems.