EAF Research Receives AIST Sustainable Technologies for Steel Manufacturing Grant

Congratulations to CIVS Research Scientist, Orlando Ugarte, on receiving the AIST Foundation Sustainable Technologies for Steel Manufacturing (STSM) Grant as PI. The project is titled “Advancing Supersonic Injection of Oxygen and Soft-Oxidizers for Reducing Carbon Emissions in Industrial-Scale EAFs”. Co-PIs include CIVS Director Chenn Zhou and CIVS Associate Director for Research Ty Okosun. Industry collaborators include Manager of Steelmaking Technology at Nucor, Eugene Pretorius and R&D Associate Director, Metals Applications at Linde, Joe Maiolo.

Congratulations to CIVS Research Scientist, Orlando Ugarte, on receiving the AIST Foundation Sustainable Technologies for Steel Manufacturing (STSM) Grant as PI. The project is titled “Advancing Supersonic Injection of Oxygen and Soft-Oxidizers for Reducing Carbon Emissions in Industrial-Scale EAFs”. Co-PIs include CIVS Director Chenn Zhou and CIVS Associate Director for Research Ty Okosun. Industry collaborators include Manager of Steelmaking Technology at Nucor, Eugene Pretorius and R&D Associate Director, Metals Applications at Linde, Joe Maiolo.

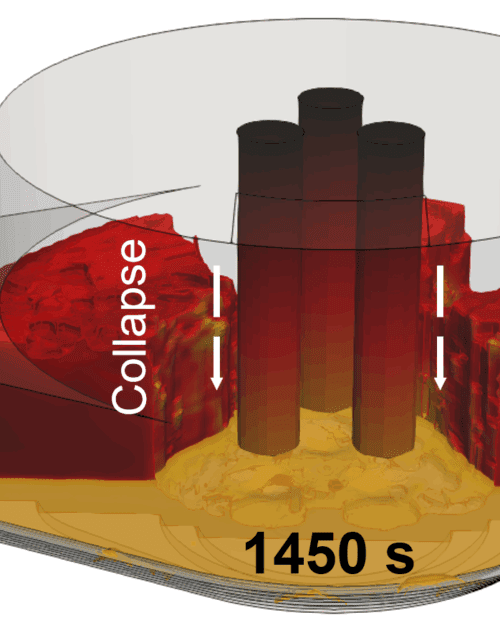

Supersonic oxygen (O2) injection is applied in EAF operations to increase molten steel stirring and enhance refining reactions. This technology reduces operation time and promotes slag foaming, which shields the electric arc, preventing thermal losses and equipment damage from excessive heating. Although this technology is widely used, further advancement and optimization are critical to reducing its chief inefficiency: the oxidation of molten steel by injected O2. Excessive O2 injection can result in significant iron oxidation to FeO in the slag. To recover yield loss, the current industrial practice is to add fossil carbon particulates, which adds cost and accounts for 40% to 70% of the total Scope 1 CO2 emissions from EAFs. A more efficient process would avoid FeO generation as much as possible, thereby minimizing the need for carbon addition. One proposed method to achieve this is to blend injected O2 with a “soft-oxidizer” such as CO2 gas. This approach maintains stirring momentum while reducing the level of bath oxidation. This project applies CFD tools to advance supersonic injection of soft oxidizers. The project aims to provide insights into how operational parameters of supersonic injection of soft-oxidizer impact refining efficiency and carbon emissions reduction in EAF operations. In addition, the project provides opportunities for students to gain hands-on experience and engage with steel industry producers and suppliers, helping them develop their career interests in the steel industry.

This grant was established to challenge university teams from engineering, scientific and mathematical departments at North American universities to submit proposals for grant funding in the theme area of sustainable technologies for steel manufacturing, including decarbonization, CO2 reduction and carbon capture, utilization and storage (CCUS), among other related technologies.

We are incredibly excited and grateful to be selected by AIST to receive the Sustainable Technologies for Steel Manufacturing Grant. While supersonic injection has been applied to EAF operations since the 1990s, there are still open questions we aim to clarify. Our goal is to make a significant impact on EAF operational performance and sustainability. Additionally, this project will engage talented students, who we hope will contribute to the steel industry in their future endeavors.