CIVS Presents in SteelSim 2021

CIVS Research Associate Professor, Dr. Tyamo (Ty) Okosun; CIVS Ph.D. student, Yuchao Chen; and CIVS Graduate Research Assistant, Vitalis Anisiuba presented three papers at the virtual SteelSim 2021 conference, the 9th International Conference on Modeling and Simulation of Metallurgical Processes in Steelmaking on October 7th, 2021.

The paper Dr. Ty presented is titled “Development of a Prediction Simulator Software for Blast Furnace Operation” Dr. Okosun presented research in progress within the Steel Manufacturing Simulation and Visualization Consortium (SMSVC) conducted by graduate and undergraduate students on the development of a tool to accelerate the physics-based prediction of conditions within the blast furnace under varying conditions. This research serves as the prelude to the development of a conceptual physics- and data-based digital twin for the blast furnace process, tying into the development of the Integrated Virtual Blast Furnace (funded by the U.S. Dept. of Energy) by researchers at CIVS. Attendees included international researchers in ironmaking and digitalization, with a common theme of the conference being the application of big data, AI, and other techniques to bring the benefits of smart technologies to iron and steelmaking.

The paper Yuchao presented is titled “Numerical modeling of scrap melting and heat transfer during electrode bore-in in AC EAF”. The research works developed a three-dimensional computational fluid dynamics (CFD) model to simulate the AC EAF scrap melting process. The model includes a solid-liquid-gas three-phase system and an arc module. A novel methodology compatible with the CFD was developed to predict the computational-cell-based arc radiative heat transfer according to the dynamic electrode movement. A scrap melting experiment was also reported in the presentation, which was implemented in a 150-ton EAF to collect the necessary data and conduct the corresponding scrap melting model validation. The simulation results and the industrial data were found to be in good agreement. The developed model was used to analyze and discuss the scrap melting profile, the arc power distribution over time, and the liquid steel re-solidification phenomenon.

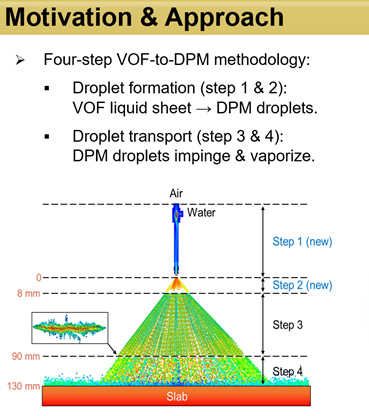

The paper Vitalis presented is titled “Numerical Investigation of Air-mist Spray in the Secondary Cooling during Continuous Casting of Steel”. The presentation was delivered with the simulation approach, assumptions/ considerations, and the results as well as some suggestions on areas to investigate. The SMSVC member companies and CIVS were duly acknowledged in the presentation. In the paper, air-mist spray cooling was modeled using the 3D computational dynamic tool to study the impingement heat transfer between droplets and the steel slab during continuous casting. Casting parameters such as air pressure, water flow rate, and standoff distance were investigated to understand their impact on slab cooling. Vitalis said, “It was a wonderful and interesting experience for me as I got to learn from the myriads of discussions in other people’s presentations as well as in mine.”