Research Areas and Projects

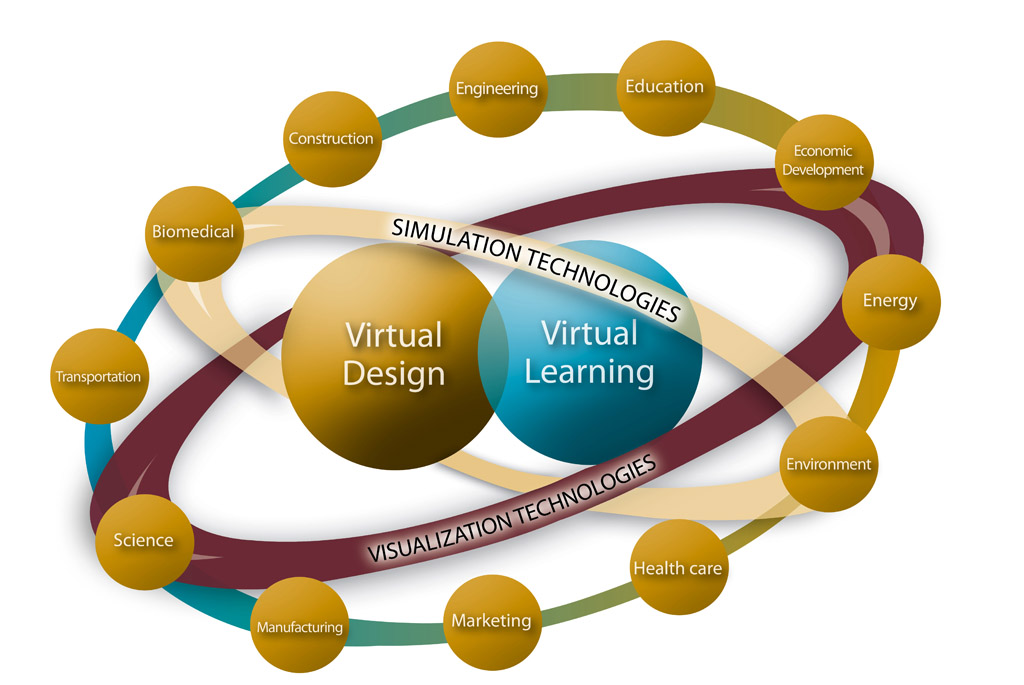

CIVS technology and resources can be applied to projects that are as expansive as the imagination. While main focuses are in Virtual Design and Virtual Learning, new research areas and technology always open new doors.

CIVS has established a broad portfolio of projects that utilize simulation and visualization technologies in collaboration with faculty, industry and community partners. Through collaboration with more than 160 external organizations, CIVS faculty, staff, and students have utilized simulation and visualization technologies to benefit more than 410 projects investigating diverse topics.

Virtual Design + Virtual Learning = Unlimited Applications

|

Virtual design enables enhanced decision making to design, optimize and troubleshoot structures, processes and products.

Virtual learning can be used to enhance teaching and learning for education and training.

- Design

Product designs and industrial processes can be numerically modeled before they are physically created to show flow patterns, chemical reactions, heat transfer, fatigue/stress and to predict mechanical failure or expected lifetime. - Optimization

Designs and processes can be updated to increase productivity, lower environmental impact, reduce energy usage and improve quality. - Trouble-shooting

Issues can be identified and corrected before or after implementation to reduce failures, mitigate flow or wear problems and avoid unnecessary downtime.

<!–

|

|

–>

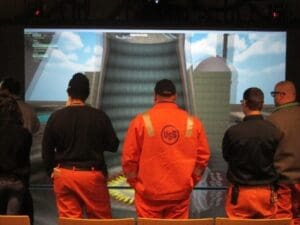

Training

VR can be used in an easy-to-understand system for virtual training in environments that might normally be physically inaccessible or impractical to recreate.

Interactive simulators provide lifelike, engaging environments where workers can be guided through work tasks and virtually experience the consequences of both safe and unsafe workplace actions.

Examples of CIVS Projects:

Virtual Design and Virtual Learning can be applied separately or together in seemingly unlimited fields. Check out some of the projects in different research areas that CIVS has been involved with by clicking on the sections:

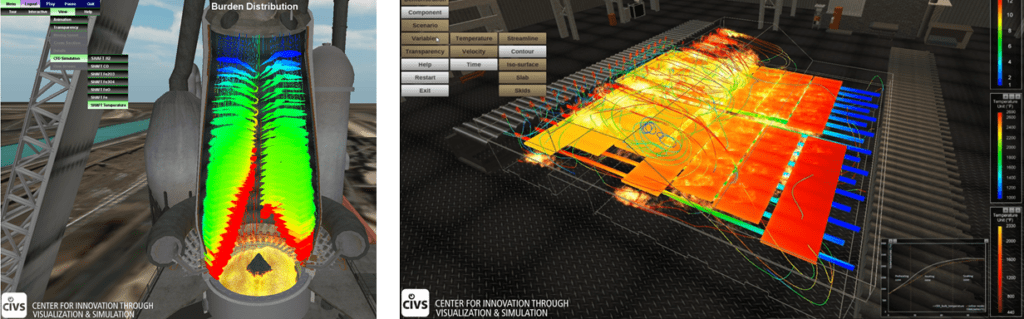

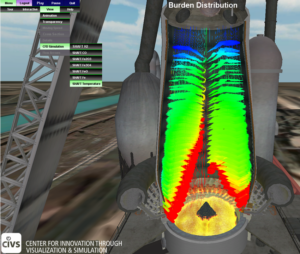

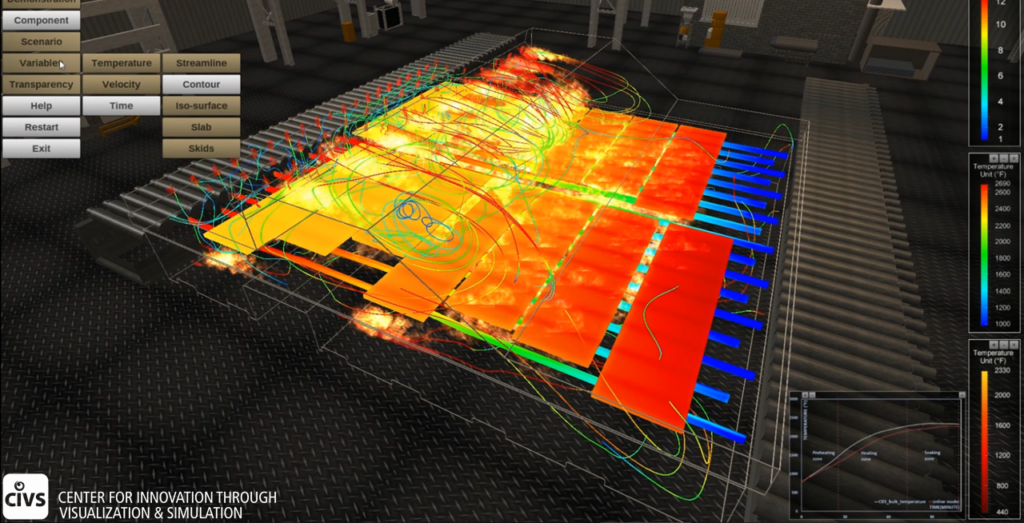

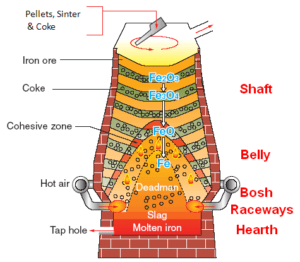

Example Project: Virtual Blast Furnace

The Problem:

The blast furnace is one of the most energy and capital intensive processes in iron and steelmaking. Complex phenomena and difficulties in taking measurements have led to using computational fluid dynamics (CFD) numerical simulations for optimization and a better understanding of processes within blast furnaces. However, increasingly complex CFD results are difficult to interpret and communicate among blast furnace personnel with varying backgrounds. Efforts have been made in the past to combine 3-D and virtual reality (VR) with CFD to improve communication and understanding, but these have only been applied to blast furnaces in a very limited fashion.

Project Objective:

Addressing issues in blast furnace operations, such as:

- Furnace Campaign Life

- Energy Efficiency

- Emissions

- Blast Furnace Downtime

- Operator Training

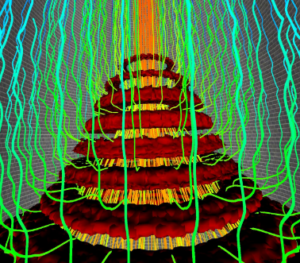

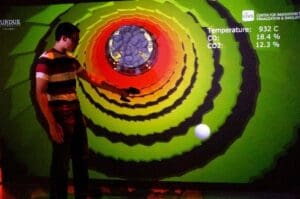

The Outcome:

High-fidelity 3D CFD models were developed by CIVS for multiple regions of the blast furnace, including the hearth, raceway, and shaft. Simulations of multiple industry blast furnaces have been conducted to investigate improvements to design, operation, and troubleshooting. By converting the numerical data to a VR environment, the development of a virtual blast furnace allows researchers, plant engineers, operators, and other personnel to bring their experiences directly into the design and optimization process. The virtual blast furnace model has also been used in the actual training process.

Some published impacts the project has made since its inception:

- Multi-million dollar annual savings in operation costs

- Reduction in downtime in some studied furnaces of up to 50%

- Five best paper awards at international conferences

2D blast furnace diagram

3D VR representation of a blast furnace diagram

Gas and burden distributions in the blast furnace Cohesive Zone

The Virtual Blast Furnace being used for training

To download the flyer/summary for this highlight project:

Example Project: High Pressure Die Casting Process Simulation for the Shop Floor

This project is being developed by Purdue CIVS with help from the American Diecasting Consortium, North American Die Casting Association, and the US Defense Logistics Agency.

The Problem:

High-pressure die casting is a complex and high-stakes manufacturing process that requires a well-trained workforce. Delving into virtual training to help improve many facets of the manufacturing process and lead to an overall better product.

Project Objectives:

- Provide interactive VR die-casting machine and aluminum melting furnaces

- Provide a greater understanding of how changes to the process affect the casting quality and life of the die

- Practice scenarios based on real-world situations

The Expected Outcome:

Deployment of the virtual interactive environments for use in workforce development across companies involved with the North American Die Casting Association as they are completed. Publication and studies will be done as the simulators reach the final states of completion.

VR interactions with the virtual die casting machine

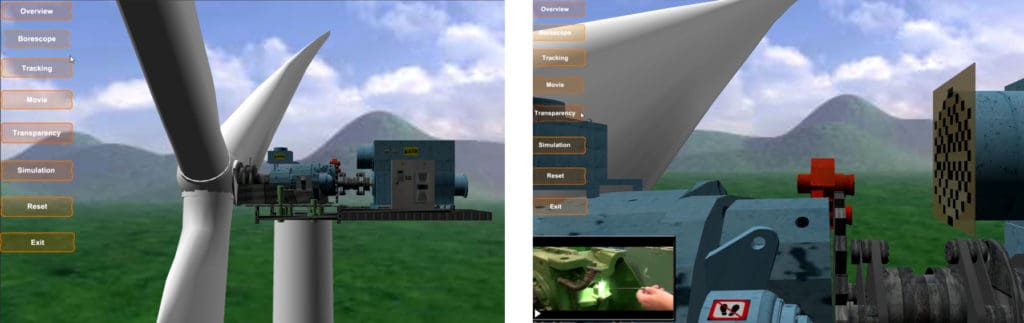

Example Project: NSF ATE Troubleshooting and Safety Simulator for Wind Turbine Technician Training

Project funded by NSF Award #1601707

The Problem:

The nation is facing a critical shortage of wind turbine technicians skilled in effective and safe troubleshooting strategies. With wind energy employers struggling to find qualified technicians, new methods of education and training are needed to meet the nation’s wind energy demands. Troubleshooting is a key skill that many current and prospective wind turbine technicians lack, resulting in significant downtime and lost energy production. Furthermore, the limited ability of students to apply concepts from the classroom to real-world scenarios is a serious issue and is compounded by hazardous conditions.

Project Objectives:

This project is developing an interactive 3D simulator incorporating numerous fault-based troubleshooting and safety scenarios in real-world situations and education modules to provide students with opportunities to practice and refine troubleshooting strategies while assuring safety. The project’s goals are to develop teaching modules for troubleshooting strategies and safety through a web-based simulator, to use said simulator in existing community college courses for specific troubleshooting and safety learning objectives, and to assess the effectiveness of the simulator and its derivative formats for improving learning objectives.

The Expected Outcome:

The wind turbine simulator will be a fully functioning wind turbine with an associated SCADA system and advanced troubleshooting capabilities built in the Unity 3D game engine.

The simulator is being used to develop scenarios that a technician may encounter on a real wind farm. This will be useful for training technicians in troubleshooting and critical thinking to reduce wind turbine downtime.

Inside of the turbine nacelle

The main menu screen

The PPE selection rack in the virtual warehouse

Example Project: Simulation and Visualization of an Airport Expansion Plan

This research was partially supported by U.S. Department of Energy Grant DE-NA000741 under the administration of the National Nuclear Security Administration

The Problem:

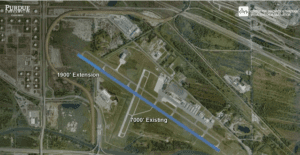

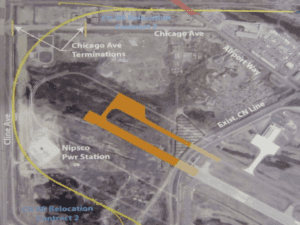

The Gary/Chicago International Airport is planning an expansion to extend the main runway and increase the capabilities of the airport. The expansion is expected to attract new business to the region and promote future economic growth.

A major issue with the expansion is a 15-foot-high railroad embankment located near the northwest end of the runway. A portion of the railroad must be relocated to meet safety regulations and to accommodate the longer runway. Simulation and 3-D Visualization have been identified as tools to aid in communicating the project to the public.

Project Objectives:

A partnership has been formed between the City of Gary and Purdue University Calumet to utilize simulation and visualization for economic planning and development of the airport.

Satellite imagery and GIS data were combined with architectural plans and images to produce a 3-D model of the existing and proposed airport along with its surrounding areas. The animation was added to the model of a plane taking off and a train traveling on the existing railroad located near the end of the runway for visualization for effective communication.

The Expected Outcome:

A video combined with 3-D renderings and animations of the existing and proposed airport were created. The project provides the benefits of simulation, virtual reality, and 3-D visualization to enhance and support the city’s capabilities for economic development and growth in the airport region.

Future uses will interface 3D visualization to more sophisticated simulation models for site location analysis, emergency facilities planning, design review, and marketing.

The virtual visualiation of the new runway

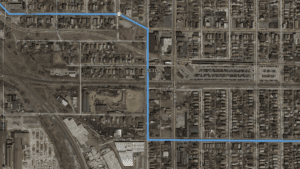

The overhead Google Earth image of the old runway

The old runway, highlighted in orange

The new expansion plan shown in a composite image

Example Project: Interactive GIS Tool for Regional Planning and Economic Development

This research was partially supported by U.S. Department of Energy Grant DE-NA000741 under the administration of the National Nuclear Security Administration.

The Problem:

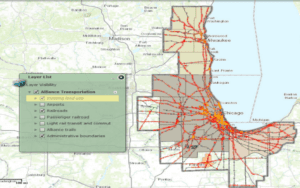

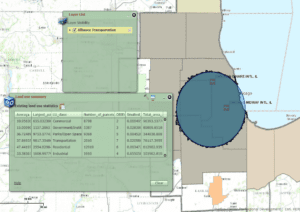

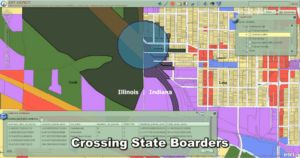

GIS data is typically maintained by organizations within individual states. Differences in data format and other issues prevent the easy sharing and merging of different data sets, making it difficult for regional planners to get a comprehensive look at GIS information that crosses state lines such as interstate transportation. Researchers and students at CIVS have worked together with the Alliance for Regional Development, NIRPC (Northwest Indiana Regional Planning Commission), the PCRD (Purdue Center for Regional Development), and others to combine data from Northwest Indiana, Northeast Illinois, and Southeast Wisconsin and create an interactive map for more effective regional planning and economic development.

Project Objectives:

The Alliance for Regional Development is a groundbreaking coalition of leaders in business, government, and academia working together to strengthen the economic competitiveness of the tri-state region. Part of the Alliance’s efforts are focused on transportation. This project is combining data and developing an interactive tool for regional planning and economic development, providing a geographic inventory from seven counties of each state for roads, major truck routes, airports, railroads, passenger and commuter rail, trails, land use parcels, population density, and administrative boundaries.

The Outcome:

The project presented at the 2nd Annual Summit of Regional Competitiveness provided:

- Geographic inventory of transportation and logistics assets across 21 counties in Indiana, Illinois and Wisconsin.

- Integrated tools that add analytic capabilities to the Regional Decision Maker system.

- Provide key information to companies that are considering moving to the region.

Early versions of the interactives tool to use for data queries

Example Project: Flood Modeling 3D Lab of Civil Engineering

This research was partially supported by U.S. Department of Energy Grant DE-NA000741 under the administration of the National Nuclear Security Administration.

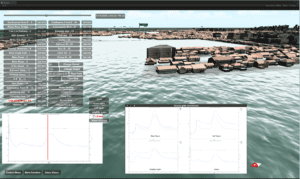

The Problem:

Flooding can lead to significant damage and loss of life. Flood planning is critical to mitigating losses in the event of disasters. In most civil engineering programs that teach about flood planning, it is not economically viable to develop a physical laboratory setup to simulate flood scenarios. A simulated flood based on a 2008 flood in Northwest Indiana was modeled to provide a virtual laboratory using HEC-HMS and HEC-RAS models but only in the form of numbers or graphs. A three-dimensional (3D) virtual lab module was needed to engage civil engineering students to explore flooding case studies, visualize hydraulic simulation results, and improve learning about flood planning.

Project Objectives:

To visualize hydraulic simulation results from HEC-HMS and HEC-RAS models, 3D models of the affected area from the 2008 Northwest Indiana flood were created including a dynamic river system, streets, bridges, and buildings. The models were used to create an interactive application using the Unity 3D game engine. Hydraulic simulation results that contained water elevation data were imported into the virtual system and the water surface was set to display the elevation. After the virtual system was initiated the control system was designed and programmed for users to fly through the environment and examine the river system at any location and at any point in time.

The Outcome:

This visualization-based lab module provided an intuitive way for hydraulic learning and it allowed users to have a visual sense of river behavior studies.

This module is being used and evaluated at four universities for Hydrology and Fluids courses. It is expected that the virtual lab will improve student learning and understanding of concepts important to flood planning and mitigation strategies.

The flooding that occurred in 2008

Interface of the flood simulator

Students using the software in an immersive theater

Example Project: Alverno Labs Visualization

This research was partially supported by U.S. Department of Energy Grant DE-NA000741 under the administration of the National Nuclear Security Administration

The Problem:

PCL Alverno, a full-service, community-based medical laboratory located in Hammond, Indiana. After providing microbiology testing services to the greater Franciscan health network in Northwest Indiana and the Chicagoland area for a time, it came time to update and start to automate some of the busy work that comes with moving samples for testing to different parts of the facility and to showcase the new technology being used to perform all the testing on all sorts of fluid samples.

Project Objective:

Develop an interactive 3D environment featuring three core devices for automating lab procedures. Work with PCL Alverno to plan the allotment of space throughout the lab, including the placement of core lab equipment. Provide a visualization of the process demonstrating the function of the three core automation devices.

The Outcome:

Students developed a virtual environment based on the facilities at PCL Alverno. The virtual models were utilized in planning the placement of critical equipment in the microbiology lab. In addition, the project team worked directly with Alverno to produce a virtual tour of the entire lab facility, following a specimen through various tests and procedures on-site. A 3D video was presented at Alverno for their Innovators Café showcase.

Specimen logging stations from the virtual lab

Images of the blood processing stations

Walk-away Specimen Processor (W.A.S.P.)

The transport garage from the virtual lab

Example Project: Interactive 3D Tour of Emergency Room Renovation for Marketing

This research was partially supported by U.S. Department of Energy Grant DE-NA000741 under the administration of the National Nuclear Security Administration

The Problem:

Franciscan St. Margaret Health is one of the largest acute-care hospitals in Northwest Indiana, where a new emergency department is under construction. A visualization was needed for marketing and showing hospital personnel the layout of the new area and key locations throughout the department. Using architectural drawings and reference images of equipment and furnishings, a 3D model of the new emergency room and equipment were created and used to generate an animated fly-through of the new space.

The Project:

3D modeling and animation software was used to create a virtual model of the emergency department with photorealistic effects such as reflections, lighting, and shadows. A series of short videos were created to take viewers through the department and highlight areas including the entrance, triage, nursing station, patient rooms, and operating room. In addition to the video, an interactive version of the 3D model was developed for further viewer exploration.

The Outcome:

A series of short HD videos were created and shown to hospital personnel to provide a virtual tour of the emergency department before construction was completed. A web-based interactive version was also developed which allowed viewers to navigate and explore the space freely using their mouse and keyboard. The interactive version also featured a guided tour and a map/compass display to help users keep their orientation as they explored the facilities.

Images from the virtual fly-through of the facility from the application:

Example Project: AMTEC Virtual Simulator

This research was partially supported by U.S. Department of Energy Grant DE-NA000741 under the administration of the National Nuclear Security Administration.

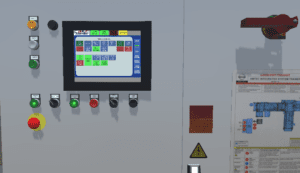

The Background:

The AIMSS (AMTEC Integrated Manufacturing System Simulator) is a physical machine designed to train students in troubleshooting for automotive engineering. The goal of the project is to provide an innovative solution for optimizing learning effectiveness. CIVS is helping AMTEC to build a virtual simulator for this machine so that users can operate it online, providing convenience and safety.

The Project:

The simulator has been fully modeled in 3D space, including the machine itself, the main cabinet and a PLC interface. The logic for the machine was added based on the behavior of the real one. Next, different troubleshooting scenarios were added. Users can use the human-machine interface (HMI) to operate the machine. Users are also provided with tools for troubleshooting and protection.

The Expected Outcome:

The final outcome is a web-based 3D Virtual Simulator, based on the physical AMTEC Instructional Manufacturing System Simulator, with fault-based scenarios that provide students with unlimited opportunities for practice and supports instructional delivery of the AMTEC curriculum for improved educational outcomes.

The physical AMTEC simulator

The virtual AMTEC simulator

Human Machine Interface of the virtual simulator

Example Project: Roundabout Simulation and Visualization for City Planning and Communication

This research was partially supported by U.S. Department of Energy Grant DE-NA000741 under the administration of the National Nuclear Security Administration

The Problem:

The Indiana Route 312 corridor in Hammond, Indiana, is a state-designated commercial truck route through a largely residential area. In partnership with the City of Hammond and Purdue Calumet’s Center for Innovation through Visualization and Simulation (CIVS) the city is in need of traffic simulation and 3D model to create a video showing the impacts of adding roundabouts to the 312 corridor. The model will include before and after conditions focused on the planned roundabout at two main intersections and will extend west to the Illinois state line, and east to Calumet Avenue.

Project Objectives:

This project integrated Geographic Information Systems (GIS) data, traffic simulation, and 3-D Visualization to show the current and planned traffic conditions and visual impacts of adding two roundabouts to the 312 corridor. Traffic data was collected using current conditions and used with VISSIM software to simulate traffic flow for both the current and future conditions. 3-D models of the corridor and surrounding environment were developed with 3DS Max software to generate an animated visualization. These elements were combined with photos and narration to generate a video showcasing the proposed roundabouts.

The Outcome:

The project provided a traffic simulation and 3-D visualization of the 312 corridor under current conditions and with the proposed roundabouts. The simulation and visualization are useful for engineering, planning, and public display. The visualization is expected to be shown in public forms to help people understand the impacts of the corridor redesign on traffic, safety, pollution, and other important elements.

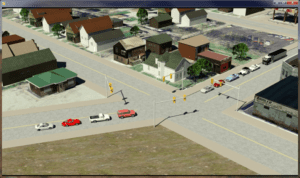

Google Earth image of the site

the virtual intersection as it was originally

showing what the roundabout would be like with traffic simulations